From the manufacturer's website:

From the manufacturer's website:

Columbia River Knives & Tools

M16-03Z: Razor-Sharp Cutting Edge

MSRP U.S. $49.99

Instead of aluminum handles, we use tough, textured Zytel® scales over a 420J2 stainless steel liner inter-frame. We over-build it for rigidity, using a 6061T6 hard anodized aluminum back spacer. And we assemble the handle with superior offset Torx® fasteners.

The handle is slightly heftier and wider than the M16, but it is exceptionally rigid. To some of us, it actually fills the hand better.

We use our tougher AUS 6M high carbon stainless steel for the blades to give greater everyday utility, and offer both Razor-Sharp and Combined Razor-Sharp and Triple-Point™ Serrated edges. All models feature the Carson Flipper, which is not only an aid to opening the blade, but acts as a positive blade guard.

First we introduced the two smaller sizes.

The M16-02Z and 12Z are tough little bulldogs, with dual grind Tanto-style blades.

The M16-03Z and 13Z is a slimmer design with a dagger style blade with a false top edge. It is ideal for a variety of carry positions.

This year we have added the hefty M16-04Z and 14Z to the series, with larger dual grind Tanto-style blades. These are full size working knives suited to large hands and heavy duty tasks. We've incorporated the patented* Lake And Walker Knife Safety (LAWKS®) into the 04Z and 14Z, which makes these larger folders into fixed blades when engaged.

All styles have Teflon® bearings and a removable Teflon plated stainless steel clothing/gear clip.

Which M16 design is right for you? It depends on the task. Think of our original aluminum-handled M16 as an Arabian stallion-purpose bred and lightweight. Think of the M16-Zytel as a Clydesdale-ready to rush a knight into battle or pull a beer wagon. Every day. Day after day.

BLADE STEEL FACTS

M16-03Z: Razor-Sharp Cutting Edge

M16-13Z: Combined Razor-Sharp and Triple-Point™ Serrated Cutting Edge

Blade: Overall length: 3.56" (9.0 cm)

Cutting edge: 3.38" (8.6 cm)

Thickness: 0.10" (0.25 cm)

Steel: AUS 6M, 55-57 HRC

Handle: Closed length: 4.63" (11.8 cm)

Weight: 3.7 oz. (105 g)

When I received this knife from the distributor it was sharp but not sharp enough for me. I sharpened the blade on my Spyderco Crock stick using the white [fine] sticks. A couple of passes over the ceramics on each side produced an edge that was hair popping sharp which is how I carry my defensive knives. In all fairness, I have had to sharpen almost all the knives I have purchased when I received them to satisfy my personal needs. Your mileage may vary.

There was no lateral [wiggle] movement in the blade in the opened/locked position. The knife pivot felt smooth in opening with no binding or roughness at the pivot area. The blade locked up fully even with a weak opening stroke that just caught the linerlock.

The CRKT M16-03Z comes with ambi thumb studs that protrude enough from the Zytel® scales to cause the thumb studs to grip both the inside and outside material on my dungaree right front pocket. These thumb studs are aggressively checkered at the ends to facilitate grabbing your thumb and would not allow the thumb to slip from the stud in opening the folder in my opinion. Because they grab the material of the pocket on both sides the knife dragged along the material as I was trying to access the folder and slowed the draw stroke considerably.

The knife carried very well in the pocket and was light enough that I did not feel the knife hanging from the clip during the day. Accessing the knife from the pocket was easy and showed the clip positioned at the best position for access yet allowing the knife to almost disappear clipped into the pocket.

The knife handled well in the flow and dexterity drills I practice allowing me to go from sabre to reverse grip and back easily and without fear of dropping it. The handle material is rough enough to hold onto but not so much that it feels rough to the touch.

Onto the testing:

Cardboard cutting test:

I used a Compaq computer box lid which was ?" thick. The knife started out razor sharp and able to cut hair off my arm easily.

I cut from the rear of the blade to the tip starting at the edge of the lid which produced 4 ˝" long cuts at the beginning with cut #1 and ended with 4" cuts at the 100th cut.

The edge was tested every 20 cuts to determine if the blade was still capable of cutting the hair on my arm. Cuts 20 and 40 showed it was still shaving with little effort. Testing at cut #60 showed it would still cut hair but the angle of the edge and pressure had to be increased to shave hair and was difficult but possible. Cut #80 showed that it would no longer cut hair from the arm even with considerable pressure and presenting the angle of attack at different degrees. The knife was more difficult to get started in the box top but was still biting well and more pressure was required to produce the same results as cut #1.

I stopped cutting at #100. At this point the blade was still cutting 4 inches deep on a blade that is 3.38" (8.6 cm) in actual cutting edge. In other words it was still slicing from front to tip deeper than the blade is long. Only enough pressure was applied to keep the knife moving in the cardboard at all times and as expected it required more pressure to perform the same cut as the knife edge became dull.

I re-sharpened the edge on a Spyderco crock stick set using the white fine sticks. It only took a few minutes and 16 strokes on both sides of the edge to bring the knife back to razor sharp and capable of cutting hair off the arm again.

Blade Tip Strength test:

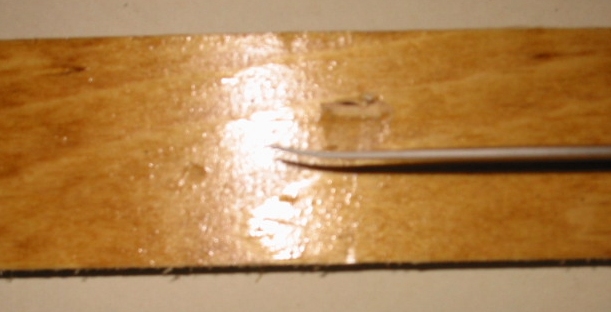

I used a piece of scrap pine I had laying around the garage for penetration testing as you see in the photos. I stabbed lightly into the wood with enough force to just bury the tip. I then attempted to rip the blade from the wood. The tip bent but did not break. I repeated this test a second time with the tip bent and ripped it out again. It bent a little further this time but did not break. I did not take the tip to 90 degrees while buried into the pine board.

I repeated the test but ripped the knife out in the opposite direction from the bent tip. It straightened the blade tip back to center. One more of these stabs bending it in the same direction but prying the tip out to 90 degrees snapped the tip off the blade. You can see tip of the blade embedded in the upper left stab test in the photo below.

Liner lock strength test:

I proceeded to dull the edge on one of my steel pepper poppers until the edge was a butter knife. It took 10 hard strokes across the steel to dull it completely. I checked after two passes and it would still cut. Two more passes showed it would still cut but was starting to lose the edge. Six more passes across the popper and it was dull enough to start the testing of the liner lock mechanism.

I put the gloves back on and drove the knife as hard as I could with an "ice pick grip" into the wood several times. Remember that the tip had been broken off at this time in the previous testing. This stabbing test was performed on an ammo crate.

No visible damage could be seen to the liner. It stayed locked up with no buckling. Upon unlocking the blade there was no signs of binding on the blade. Unlocking the blade was as smooth as before the testing.

I rechecked the lateral play of the blade when locked open and discovered that now we had a very slight "wiggle". It was not loose but there was a little play in it whereas before there was none. If you look closely you can see some cloth material on the thumb stud in the picture below from my dungarees.

Conclusions from tests:

1. The CRKT M16-03Z is a very nice knife for the money. The AUS 6M high carbon stainless steel takes a good edge rapidly after becoming dull. It takes awhile to dull the edge past where it will shave hair off the arm. It is easily re-sharpened after fairly heavy use. I did not take the edge to a "butter knife" where I would have to reset the primary grind lines on the knife. Under normal circumstances you would not take the knives to that level of dullness. If you do wait too long and take the edge to that level other equipment is necessary other than the sharpening stone or ceramic sticks unless you want to spend a good long time getting the primary grind back to where it belongs so you can sharpen the knife properly.

2. The CRKT M16-03Z 420J2 stainless steel liner inter-frame is rugged enough to take multiple stabbing blows into a fairly hard medium and not break the tip off or have the liner collapse from the stresses produced by this action.

3. Overall the knife feels comfortable and carries well in the pocket with the exception of the thumb studs that are too sharp and protrude too far out past the Zytel scales. They grab the pocket material from both sides and slow the draw stroke as well as ruining the pants material in short order.

4. It is easily controlled in the hand while slicing the box top until around cut # 70 where I became cognizant that I had to hold the handle tighter. I had to apply more force to accomplish the same cuts as the edge dulled with each stroke. The handle fits my hand very well and is easily controlled even when the cutting got more difficult. I have an average size hand for a man, not being a "big boy" nor a petite person at 5' 10" and 175 lbs. Your mileage may vary.

5. The knife as it came from my distributor was better than I expected for the money spent. I could carry this knife with confidence that it would perform everything I might need it for before getting back to the sharpening stones.

6. I do not like the thumb studs as they came on this model. CRKT needs to radius the edges of the studs quite a bit. As it is, they do not need to be that aggressive to allow a good purchase by the thumb when opening the blade.

7. I like the Carson Flipper on the backside of this knife. It took only minutes to learn how to use quickly and is a second way to open the blade instead of utilizing the thumb studs.If I could get CRKT to send me one without the thumb studs I would carry this knife daily for chores and defensive needs and not feel lacking. That says a lot as I usually carry knives that cost several times what this tactical folder cost me to destroy.

One last thing before I close. The pictures did not come out that well. I'm not a photographer.I will try to get better at photos as the tests progress. Your patience in this matter is greatly appreciated.

Brownie

Visitor's opinion (February 28th, 2004)

Brian, obviously a US military person, stationed in Bagdad Iraq, was kind enough to send us the followings, regarding this knife.

I have the tanto blade version of this knife, and could not be happier. It is an excellent tool, it copes easily with everthing I ask of it from day to day chores to self defense. I love the Carson Flipper, which is so simple but efective. The flipper works better on the 4 inch blades than on the three inch blade my friend has. The liner lock always feels secure, and after two months regular use in Iraq, hasn't shown any wear or tear. This is the best knife I've ever had, and wouldn't consider changing.

Thanks Brian, and try be safe there!

Visitor's opinion (April 20th, 2004)

Nick Stasi, from IL, USA, was kind enough to send us the followings, regarding this knife.

I've been carrying the M16-14Z (the larger knife) for close to a year now. I agree that the thumb studs protrude a little too far and grip a lot, as does the main screw holding the blade in. The paint on the pocket clip has rubbed off a lot on the outer side, but the inner side of the clip looks new still. Its a heavy knife and pretty large compartively, but it suits me great. I'm hoping to carry this knife as long as I possibly can. Its rugged and durable and has outlasted nearly every other knife I used to carry.

Thanks Nick!

Visitor's opinion (July 9th, 2004)

Stephen Kipp, from VA, USA, was kind enough to send us the followings, regarding this knife.

I bought a CRKT M-16/14 a few months ago for about $48 at the exchange on base. Ver hefty for a folding knife. I am used to fixed blade knives, and my only experience with foldwers is limited to my very small CF Benchmade Mel Pardue. That said, I have a great dealof experience breaking knives and tools. I performed the tip and lock tests on this knif, and couldn't break the tip off in douglas fir, pine, or pressure treated lumber. The tip just ripped the wood up. Sharpening is pretty easy on 150 grit sandpaper glued on a wood block. Shaving sharp out of the box, and easily resharpened. The AUS-8 steel has earned a lousy reputation on forums, but it seems to be good steel on this particular knife. I'm pleased, and now carry this over my CS kobun. Price, quality, and performance are all above expectations.

Thanks Stephen!

Visitor's opinion (September 9th, 2004)

Rob, from Saint Louis, MO, USA, was kind enough to send us the followings, regarding this knife.

Lousy knife... In short order, the lock on mine began to fail with little pressure on the spine. The liner became worn quickly, then it was simply pushed aside by the poorly shaped tang.

Thanks Rob!

Visitor's opinion (December 15th, 2004)

Mortimer, from Clevelant, USA, was kind enough to send us the followings, regarding this knife.

I have the M-16/14 in carbon fibre and AUS-118 steel. After 3 years of moderate use, the carbon handle still doesn't have a scratch on it, nor does the bead-blasted blade. I sharpen about twice a year. I believe the factory claims a 59-60 Rockwell hardness. The liner does not wiggle, and is as tight now as it was when new. The Carson flipper is ingenious. The belt clip did loosen very slightly, and bend so that it wasn't gripping my pants as securely. Using a torx bit to remove the clip, and rebend it back for better tension solved that minor problem. Bearings are still butter smooth, though I do clean all the surfaces periodically. This knife looks fantastic, and performs very well for its price of $100. Only Damascus could improve this fine knife.

Thanks Mortimer!

If you also own the knife tested above, please click here to send us your opinion about it. We will enter your opinion here, so that visitors can read your opinion, as well as ours.